Basic Info

Leachate, flue gas, fly ash and slag are the main pollutants in waste incineration plants.Flue gas is the gaseous product of waste burning,comprising a large amount of granulas with abundant dioxin absorbed on them. Incineration plants generally use wet flue gas absorption, bag dust cleaning, etc. to remove the pollutants in the flue gas.

Sack-dusters collect a considerable amount of granulas, namely fly ashes, hence, if the dust catching job isn’t done well, the level of dioxin emission will be respectively high.

With nearly 30 years of development history and number of experts engaged in air pollution control, like dust removal,desulfurization and deodorization, we has accumulated a wealth of experience and technology advances in the engineering sector.

We provide highly efficient dust collector for coal-fired waste incineration plants, which has been consistently recognized by customers.

Principles

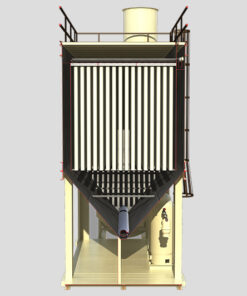

Waste incineration dust collector is a new type of high efficient pulse dust collector, based on and modified from bag filter, composed of ash bucket and chambers divided upper case, middle case and lower case.

During operating,dusty gas enters into ash bucket through air duct, coarse particles directly land on the bottom ground by the effect of gravity, fine dust turn upward into middle and lower case and attach on the out surface of the filter bag.Processed air move into upper case and meet net gas collection tube, exhaust duct then discharge into atmosphere by exhauster.

Dust cleaning process starts with cutting off the net gas outlet duct of chamber,making the filter bag in a state of no air through, namely chambers separated dust cleaning under the condition of no ventilation.

Then turn on pulse valve, clean dust by pulsing injecting compressed air,and make sure valve turn off time is longer enough to guarantee the dust and powder falling from filter bag sediment to the ash bucket,which avoid dust and powder stick on the adjacent filter bags with air flow after getting away from bag surface,dust removal thoroughly, and automatic control available on exhaust valve, pulse valve and discharge valve by programmable controller.

Advantages

- All steel structures are treated with an electrophoretic coating resistant to a 40-hour salt spray test;

- Easy assembly with modular design, no welding, easy on-site assembly;

- The compact, simple and flexible combination of structural design to meet a variety of occasions;

- Multiple choice of filter bag materials to meet a wide range of industrial process applications;

- Pulse diaphragm valve, sequential controller and differential pressure meter are all made in Italy MECAIR original products;

- Cleaning system using “Teco Environmental Systems Australia” “pulse bag GOCO cleaning control design technology”

Control Model

- User-selectable;

- Sequential control

- Differential pressure control

- Intelligent control (extend the life expectancy of filter bag)

Other advantages

- Simple maintenance

- “Zero” leakage emissions

- Lower compressed air consumption

- Lower operating costs

العربية

العربية Español

Español Русский

Русский 中文 (中国)

中文 (中国)

Reviews

There are no reviews yet.