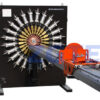

Specification

- Model: DLN-24-6

- Cage wire quantity: 8/10/12/14/16/18/20/22/24

- Ring space: can be set at any value

- Cage outer diameter: 100-200 mm

- Rail length: standard 7 m, up to 10 m can be customized

- Input voltage: 380V(2-phase) or customized

- Power frequency: 50/60Hz

- Designed max capacity of transformers: 80KVA

- Instant power in sync mode: 36KVA

- Instant power in sync(time-sharing) mode: 18KVA

- Transformers: 2sets

- Air pressure: 0.6-0.8MPa

- Required air flow: 300L/min

- Cooling method: natural cooling

- Weight: about 1000KG

Features

- One machine can weld the whole cage, including top collar, cage body and bottom cap.

- Quick welding speed, e.g. for a 12-wire cage, one ring takes only 0.18s.

- Automatic cage pulling, ring space can be set in the program through the user-friendly interface.

- The cage pulling carriage is equipped with bearings, runs on the rail with linear guides, it’s smooth and precise.

- Function of bad weld detection and auto re-welding.

- Material selection, different welding parameters for mild steel, galvanized steel and stainless steel.

- Auto compensation gives enough space to insert the ring when the ring distance is short.

- Ring space precision is 0.1mm; cage pulling speed is 0.4m/s.

- Rails and material shelf equipped and connected to the machine. The front end of the rail is adjustment-free. Good linearity can be achieved for wire cages.

- Four air tanks, short air route inside the machine ensures quick response of the cylinders.

- 25mm thick front plate resulted from one-time machining, firmly secure that the welding cylinders are on the same plane and perpendicular to the axes, thus the linearity of the cage can be ensured.

- Stroke-adjustable cylinders increase welding speed, pre-pressing only takes 0.08s.

- Equipped with powerful micro-computing unit.

- Sync/Time-sharing mode can put two transformers work at the same time or one after another, secure good welding quality even when the power supply is not very sufficient.

العربية

العربية Español

Español Русский

Русский 中文 (中国)

中文 (中国)

Reviews

There are no reviews yet.