Ultimate Goal

Ultimate Dust treatment goal in steel industry: the prevention and control of air pollutants produced from the iron and steel industry, mainly using sack-dusters to filter the massive and harmful soot and dusty particles in the the air pollutants while recycling useful materials.

Applications

- Original mine

- Fuel crushing

- Screening

- Transport

- Coking

- Sintering

- Raw materials storage area

- Blast furnace raw materials

- Feeding facilities

- Blast furnace pulverized coal

- Blast furnace smelting

- Hot metal pretreatment

- Converter steel making

- Electric steel making

- Steel making raw materials system

- Molten steel refining

- Slab cutting

- Hot rolling, cold rolling production line facilities

- Flammable and explosive dust,soot and gaseous pollutants removal

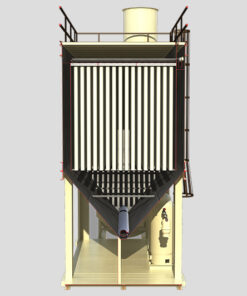

Features

- High dust removal efficiency,up to 99.9% to 99.99%;

- Stable operation, not affected by the resistivity of dust;

- Not restricted by dust type, concentration difference or particle size

- Adapt to process conditions and big loading changes,emission concentration can lower to 30mg/Nm3, even 5mg/Nm3 available.

- Large and flexible air handling capacity, smallest to 1000m3/h and biggest to 2*106m3/h above.

- Relatively small area covering;

- Filter bag maintenance and replacement can be operated without filtration downtime;

- High efficiency and stable dust catching performance,reclaim useful raw materials and other materials in large quantities;

- Can spray limestone, dolomite, etc. in the dust removal system pipes to absorb the oil mist, asphalt and tar in the flue gas, and then remove them through the dust remover;

- Possible to further adsorb the nonabsorbent dust accumulated on the filter bag and protect the filter bag from being adhered.

Advantages

- Modular structure, suitable for long-distance transport, easy assembly

- Simple and compact structure

- A variety of specifications to choose from

- A variety of media can be adapted to a variety of industrial and process

- Italy MECAIR intelligent controller, high-quality diaphragm valve, differential pressure meter

- Control mode: manual/automatic/differential pressure/intelligent

- Short delivery time

- No leakage, “zero discharge”, emission standards below to 20mg or less

- User-friendly design, easy maintenance

- Exclusive design can greatly reduce the consumption of compressed air, saving energy with online cleaning and off-line cleaning two options

Air Volume Process

Unrestricted, modular structure, unlimited expansion.

العربية

العربية Español

Español Русский

Русский 中文 (中国)

中文 (中国)

Reviews

There are no reviews yet.