Applications

Corrugated board production line conveyor belts, corrugating machine conveyor belts are special designed for double-faced corrugating machines. As one of the main spare parts of corrugating machine automatic production line, they are essentially functioning in making sure the smooth transportation and the rapid evaporation of wet.

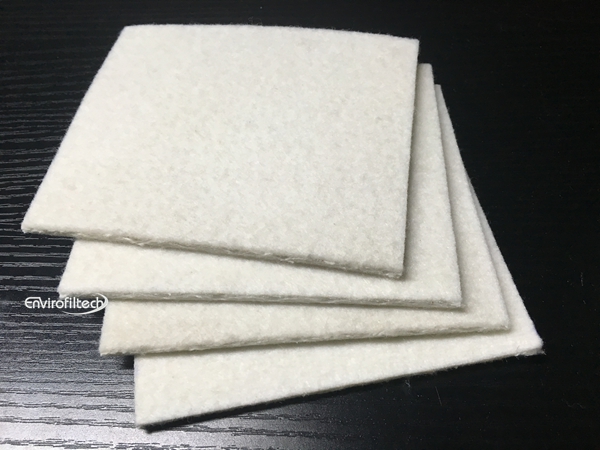

It is designed and created at the base of traditional cotton belt and non-woven belt, with various excellent physical properties, like great tensile strength, geometry size, coefficient of friction, air permeability, anti-static and high temperature resistance, which enables it double life expectancy than congeneric products.

Technical Features

- Using suede as cardboard contacting area for keeping cardboard surface smooth and even;

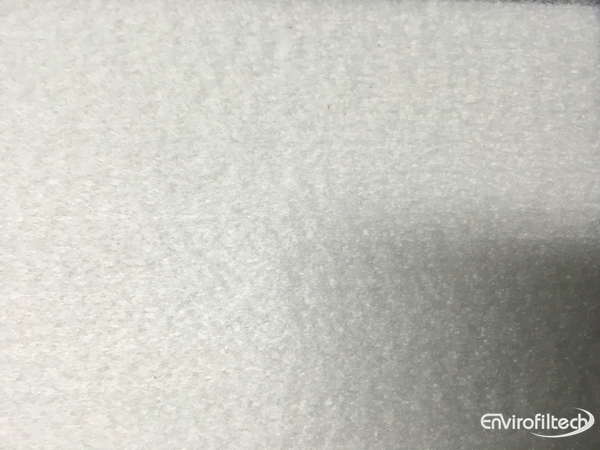

- Three -dimension fibrous distribution inside structure, high steam permeability, energy-saving,edge cuttable and no breakage;

- Cotton suede surface, wear-resistant, no cracking, increased life span and 100 square meters cardboard production available on every meter belt;

- Connection hook covered with corrugated belt itself, no impression generated;

- Anti-shrinkage treated and shrinkage less than 1.5%

Performance Index

10mm Thickness

| Density | g/㎡ | 4600 |

| Thickness | mm | 10±0.5 |

| Air Permeability | m³/㎡·min ·40H2O | ≥25 |

| Breaking Strength | kg/m | ≥5000 |

| Working Temperature | Below 180℃ | |

12mm Thickness

| Density | g/㎡ | 5500 |

| Thickness | mm | 12±0.5 |

| Air Permeability | m³/㎡·min ·40H2O | ≥20 |

| Breaking Strength | kg/m | ≥5500 |

| Working Temperature | Below 180℃ | |

العربية

العربية Español

Español Русский

Русский 中文 (中国)

中文 (中国)

Reviews

There are no reviews yet.