Basic Info

At present, nearly 10% processed dust and scraps are generated in the production of Chinese domestic industrial braking friction materials.

In total, annually thousands of waste emerged in national mechanical and automobile friction material industries.

In terms of fine asbestos fibers and a few heavy metal copper powders are the essential components of these waste dust and do great harm to human health, respectively high dust removal efficiency and reliability are the exclusive required properties of those specialized dust collectors in friction material industries.

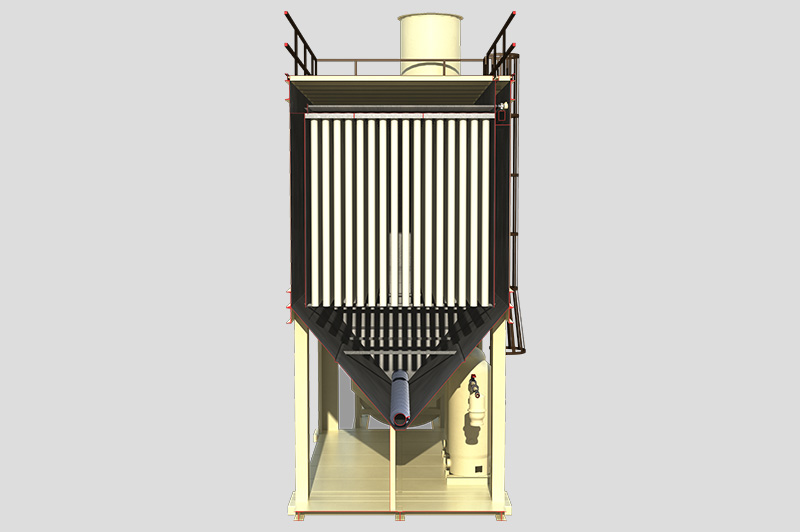

Direct at such dust, we designed and created the corresponding high efficient dust catchers for friction materials industries.

Commitment

- Dust collector components are warranted for 36 months

- Differential pressure less than 1300 Pa

- Life expectancy more than 36 months

Advantages

- All steel structures are treated with an electrophoretic coating resistant to a 40-hour salt spray test

- Easy assembly with modular design, no welding, easy on-site assembly

- The compact, simple and flexible combination of structural design to meet a variety of occasions

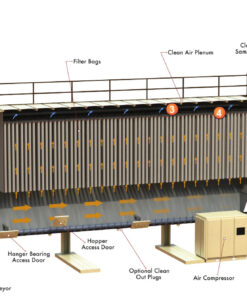

- Multiple choice of filter bag materials to meet a wide range of industrial process applications

- Pulse diaphragm valve, sequential controller and differential pressure meter are all made in Italy MECAIR original products

- Cleaning system using “Teco Environmental Systems Australia” “pulse bag GOCO cleaning control design technology”

Cleaning Control

- User-selectable

- Sequential control

- Differential pressure control

- Intelligent control (to extend the life of the bag)

Other Advantages

- Simple maintenance

- “Zero” leakage emissions

- Lower compressed air consumption

- Lower operating costs

Project Case

GLORY Zhuhai Greely Friction Materials Co., Ltd. purchased 10 sets of dust removal system and completed the project in 2014,air volume process up to 25,000-45,000 m3 / h.

العربية

العربية Español

Español Русский

Русский 中文 (中国)

中文 (中国)

Reviews

There are no reviews yet.