Advantages:

- Increase system filtration capacity by 50-150% without major changes to the dust collectors.

- Significantly extend pulse cleaning intervals and fine dust emission under the same operating conditions.

- Significantly reduce system pressure drop and energy consumption.

- System cleaning efficiency markedly increased with the effective increase of bag to bag distance.

- Bag life extended due to significant reduction of fatigue damage to the bags due to bag to cage impact.

All currently available filter media can be used:

Polyester, Homopolymer Acrylic, Polyphenylene Sulfide (PPS), Aramid (Nomex), Polyimide (P84), Polypropylene

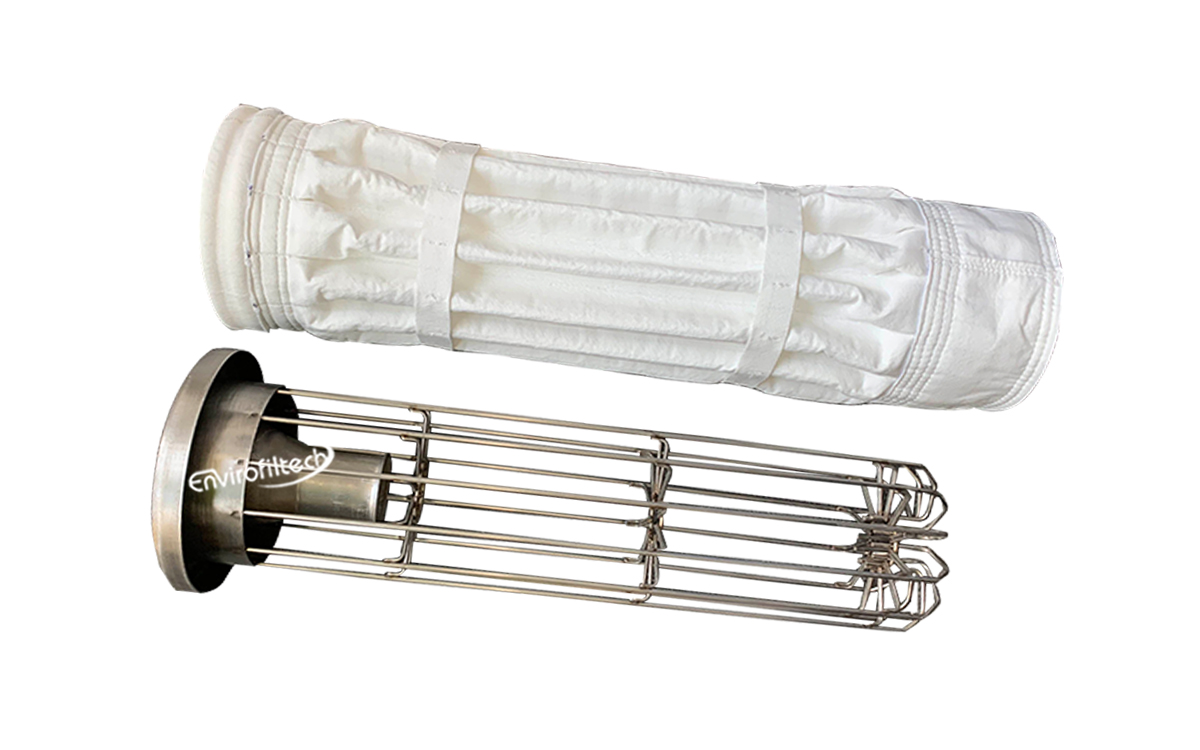

4 types of common pleated filter bags(star bags):

High temperature STAR BAGS;

Normal temperature STAR BAGS;

Anti-static STAR BAGS;

PTFE membrane STAR BAGS.

Pleats number of common star bags:

8 , 10 , 12

Application

Flue gas treatment and dust removal system:

Iron plants, steel plants, ferroalloy plants, refractory plants, foundries, power plants, waste incinerators, coal-fired boilers, fluidized bed boilers;

Production site:

Asphalt, concrete mixing, building materials, cement ceramics, lime, petroleum, etc.;

Smelting flue gas filtration of rare metals:

Aluminum electrolysis, lead, tin, zinc, copper;

Liquid-solid separation and fine material recovery:

Chemicals, coke, carbon black, dyes, pharmaceuticals, plastics and other fields;

Dust management and purification collection:

Mining, grain processing, flour, electronics industry, wood processing, etc.

Pleated Filter Cage

Cages and bags are the main parts for dust clear system, the quality of the cages and the mating demensions with the bags is very important. It will influence the bag life and filtering quality.

We have special technical people to research and analysis the damaged bags for different condition bag house, to improve and creative the design of the cages. To help the customers to use the right bags and cages and offer the technical service.

Practical application

العربية

العربية Español

Español Русский

Русский 中文 (中国)

中文 (中国)

Reviews

There are no reviews yet.