Portable Dust Collector

Portable dust collector is an air cleaning product, designed for on-site dust collection, equipment suite, protecting operators and workers from dust harm, maintaining clean working environment and letting out purified air.

Optional in various working conditions, with exclusive pulse injection system, economical, practical, competitive quality and price, low noise, portable and easy assemble, our product has been widely applied to smoke dust cleaning and granular removal.

Mobile Vacuum Cleaner

- VCIP mobile vacuum cleaner is a relatively unique product in current commercial vacuum cleaner market, unlike other existed products, it arms with following properties:

- Continuous working without any downtime.

- At present, most existed vacuum cleaner can’t keep working without any downtime and has to shut it down for components cooling within 1 hour.

- Featured with strong dust sucking ability, industrial mobile vacuum cleaner can easily suck glass fragments, nuts and screws in.

- Under regular condition, VCIP mobile vacuum cleaner can keep working 1200 hours without bag unloading and cleaning and its life expectancy is up to 1800 hours.

- The inlet of VCIP mobile vacuum cleaner is dust swirling structured.Once dust encounters into the structure and swirling move down toward the dust bucket, only few of the light dust move up,thus,dealing with filamentous and fibrous dust,for instance, mineral cotton fiber, in a easy way.

- Lack of dust swirling structure design in other vacuum cleaners, filamentous and fibrous dust encountering will cause surface twining in filtration process and cleaner blocking.

- Currently, starlike filter bag, flat filter bag and filter cartridge are widely adopted in most vacuum cleaners,dust easily gets accumulated and bag unloading and cleaning after use are highly required, very cumbersome to operate.

- By using circular filter bag on our products, dust can not accumulated on the bag surface and dust removal can move smoothly, its life expectancy also gets extended.

At present, most vacuum cleaners in the commercial market have following three major drawbacks:

- Small mobile operating radius

- Manually cable control required

- Can’t meet the needs of dust removal in massive area.

With electrical and retractable cable control and equipped based on practical conditions, VCIP not only has an increasement of mobile operating radius but also largely deduces cleaners’ working loads.

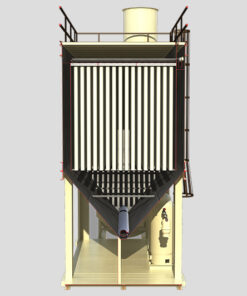

Industrial Dust Collector

Applications

Industrial dust collector is a industrial manufacturing equipment used for collecting and gathering waste media particles, dusty smoke and oily water.

Features

- High dust removal efficiency,up to 99.9% to 99.99%;

- Stable operation, not affected by the resistivity of dust;

- Not restricted by dust type, concentration difference or particle size

- Adapt to process conditions and big loading changes,emission concentration can lower to 30mg/Nm3, even 5mg/Nm3 available.

- Large and flexible air handling capacity, smallest to 1000m3/h and biggest to 2*106m3/h above.

- Relatively small area covering;

- Filter bag maintenance and replacement can be operated without filtration downtime;

- High efficiency and stable dust catching performance,reclaim useful raw materials and other materials in large quantities;

- Can spray limestone, dolomite, etc. in the dust removal system pipes to absorb the oil mist, asphalt and tar in the flue gas, and then remove them through the dust remover;

- Possible to further adsorb the nonabsorbent dust accumulated on the filter bag and protect the filter bag from being adhered.

Commitments

- Dust collector components warranted for 36 months

- Differential pressure less than 1300 Pa

- Life expectancy of filter bag more than 36months

Advantages

- All steel structures are treated with an electrophoretic coating resistant to a 40-hour salt spray test

- Easy assembly with modular design, no welding, easy on-site assembly

- The compact, simple and flexible combination of structural design to meet a variety of occasions

- Multiple choice of filter bag materials to meet a wide range of industrial process applications

- Pulse diaphragm valve, sequentialcontroller and differential pressure meter are all made in Italy Mecair original products

User selectable cleaning control

- Pulse sequential control

- Differential pressure control

- Intelligent control (extend the life of the bag)

Cleaning system using “Tyco Environmental Systems Australia” of the “pulse bag GOCO cleaning control design technology

Other Advantages:

- Simple maintenance

- “Zero” leakage emissions

- Lower compressed air consumption

- Lower operating costs

العربية

العربية Español

Español Русский

Русский 中文 (中国)

中文 (中国)

Reviews

There are no reviews yet.